Ball bearings

Ball bearings are a sub-category of roller bearings. In ball bearings, rolling elements between a inner ring and an outer ring reduce frictional resistance, in contrast to lubrication in the case of plain bearings. The rings secure axles and shafts by absorbing radial and/or axial forces, depending on the structural form, while allowing the rotation of the shaft or components mounted on an axle (for example, a wheel). Rolling friction mostly occurs between the three main components of inner ring, outer ring and rolling element. Since the rolling elements in the inner and outer ring roll on hardened steel surfaces with optimised lubrication, the rolling friction of these bearings is relatively low.

Deep-groove ball bearings

Deep-groove ball bearings are particularly versatile. In addition to allowing the absorption of radial loads, they simultaneously enable the absorption of axial loads in both directions. They are of simple construction, durable in operation and maintenance and suitable for high to very high rotational speeds.

Axial deep-groove ball bearings

Axial deep-groove ball bearings are suitable for supporting axial loads but must not be subjected to radial loads. Axial deep-groove ball bearings are not self-retaining and consist of the shaft washer, housing washer and ball set retained by a cage. Depending on the application, they are manufactured as single or double-direction bearings. Single-direction axial deep-groove ball bearings are suitable for absorbing axial forces in one direction and can thus support the shaft to one side. Double-direction axial deep-groove ball bearings, by contrast, can absorb axial forces in both directions and thus, as locating bearings, they support the guidance of the shaft to both sides.

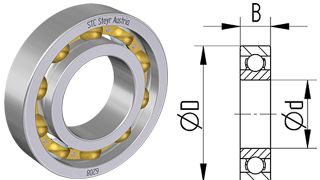

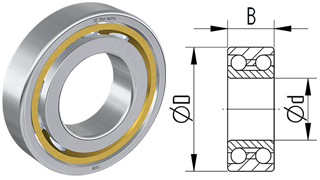

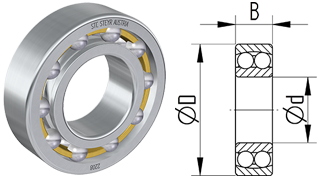

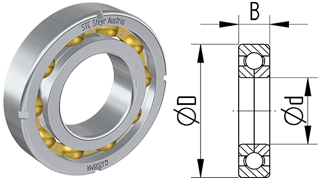

Angular contact ball bearings

Single-row angular contact ball bearings are non-separable bearings with solid inner and outer and rings whose raceways are offset against each other in the direction of the bearing shaft. This allows angular contact ball bearings to be subjected to radial and axial loads. They only absorb axial forces in one direction and thus need to be adjusted against a second bearing. Single-row angular contact ball bearings are designed for high rotational speeds; however, their angular adjustability is very low. Considerably higher running noise occurs due to skewing and the service life is reduced by an additional load. Single-row STC-Steyr® angular contact ball bearings are produced in two variants – DIN 628-1 – the standard and universal versions. The contact angle is available as 25°, 30° and 40°. The greater the contact angle, the higher the axial load-carrying capacity of the angular contact ball bearings. The standard version of angular contact ball bearings is intended for bearing arrangements where only one bearing is used for each bearing point. Single-row angular contact ball bearings in the universal design are intended for fitting in pairs in X, O or tandem arrangement. They are matched in production in such a way that bearings of the same size and design can be directly installed in the aforementioned arrangements.

Spindle bearings

Spindle bearings are single-row angular contact ball bearings comprising solid inner and outer rings and ball and cage assemblies with solid window-type cages, which are not separable and produced in open and sealed versions.

Spindle bearings have restricted tolerances and are particularly appropriate for bearing arrangements with the most stringent requirements for guidance accuracy and speed suitability. They have proved to be highly appropriate for the bearing arrangements of spindles in machine tools.

Self-aligning ball bearings

Self-aligning ball bearings are double-row, self-retaining units comprising outer rings with concave raceway, inner rings with cylindrical or tapered bore and ball and cage assemblies. They thus allow angular adjustment and are not susceptible to skewing of the shaft relative to the housing. They are therefore particularly suitable for bearing applications in which larger shaft deflections or alignment errors are to be expected. These bearings are available in open and sealed versions.

Four-point contact bearings

Four-point contact bearings are single-row radial angular contact ball bearings, whose raceways are formed in such a way that axial loads can be accommodated in both directions. Radial loads of only a fraction of the axial load can be absorbed. In the axial direction, four-point contact bearings require significantly less space than double-row bearings.